Piccotex 120

- Technical Data Sheet Piccotex™ 120 Hydrocarbon ResinApplicationsA···

Technical Data Sheet Piccotex™ 120 Hydrocarbon Resin

Applications

Adhesives/sealants-b&c

Bookbinding

Carpet construction

Case & carton sealing closings

Casting wax

Commerical printing inks

Concrete

Film modification

Hygiene adhesives

Labels non food contact

Marine

Packaging components non food contact Packaging tape

Polymer modification

Protective coatings

Roofing

Solvent borne packaging adhesives Specialty tape

Tape non food contact

Tires

Product Description

Piccotex™ 120 hydrocarbon resin is the highest softening point member of in a series of highly stable, water white, thermoplastic materials based on purified aromatic monomers. These resins have outstanding hot tack; heat sealability; resistance to discoloration; acid, alkali, and moisture resistance; and stability to elevated temperatures encountered in compounding. High initial and retained gloss, and improved application speeds on curtain coating and roll coating equipment. Piccotex™ 120 complies with some FDA regulations for applications involving direct contact with food. Compliance with a given regulation in a specific situation should be verified prior to use in a

food contacting application.

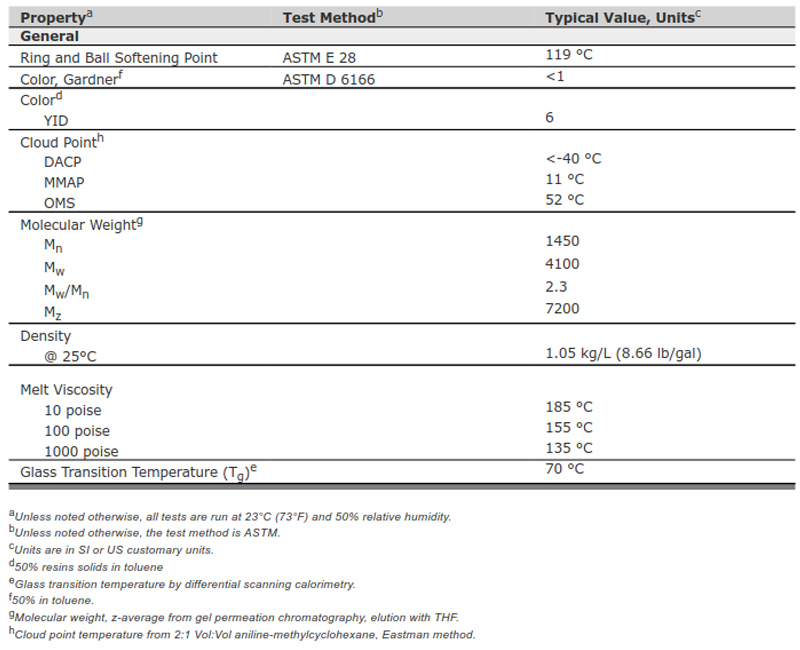

Typical Properties

Compatibility and Solubility

Compatible in useful proportions with paraffin, chlorinated paraffin, microcrystalline waxes, low molecular weight polyethylenes, high styrene resins, vinyl toluene polymers, ethylene-vinyl acetate (EVA) copolymers, and many common plasticizers. Soluble in aliphatic, aromatic, and chlorinated hydrocarbons; ethers; esters; nitroparaffins; and benzyl alcohol. Insoluble in lower alcohols, glycols, and water. For low or zero VOC systems Piccotex™ 120 is soluble in the VOC exempt solvents t-butyl acetate and perchlorobenzenetetrafluoride (PCBTF) and will tolerate some acetone and/or methyl acetate as a diluent in solvent systems based on TBA and/or PCBTF. VOC exemptions and environmental regulations vary regionally, and compliance with local standards should be verified before any claims about VOC content are made.

Packaging

Pastilles, in multi-wall paper bags (50 lbs, 22. 7 kg net wt).

Storage

Due to the thermoplastic behavior, pastillated and flaked resins may fuse, block or lump. This can be accelerated under any of the following conditions: 1) above ambient temperature, 2) prolonged storage, 3) pressure, e.g., stacking pallets, or a combination of these conditions. This is particularly applicable for low softening point resin grades.

In order to maintain the flake or pastille shape, we therefore recommend storing the material in a temperature-controlled area, be careful with stacking material or applying pressure and preventing prolonged storage.

It should be noted that lumping does not have a negative impact on the product specifications. Due to the nature of the product, claims regarding lumping cannot be accepted.

Resins are prone to gradual oxidation, some more so than others. This could result in darkening and/or it could have an adverse effect on the solubility of the resin in organic solvents or on its compatibility with polymers. Accordingly, it is recommended that strict control of inventory be observed at all times, taking care that the oldest material is used first.

精细化学品

精细化学品